Why visit ACE ’24?

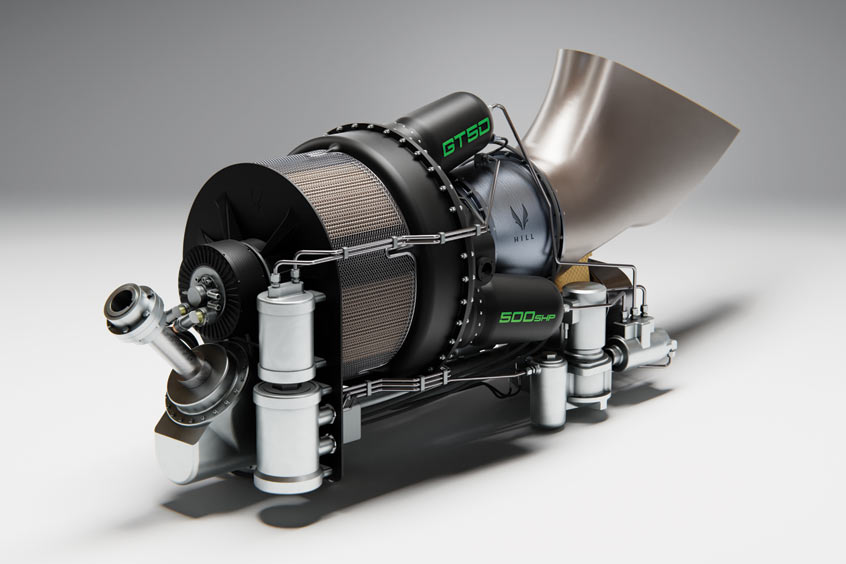

Hill Helicopters has unveiled its Hill GT50 light turbine engine, designed specifically for the recently announced Hill HX50 luxury personal helicopter. The company describes it as an elegant and intellectual combination of time-tested, proven engine technologies and turbine engine advancements.

“The GT50 was designed and developed by a team of industry veterans, using methods, tools and techniques pioneered over decades,” says Hill Helicopters president and CEO Jason Hill. “It is an intelligent ensemble of proven ideas and architecture, embodied into a new engine that fully exploits modern advancements, manufacturing methods and supply chain opportunities to fulfil a specific market need.”

Designing its own advanced engine allowed Hill Helicopters to move outside the constraints of existing engines first designed in the 1950s, it says, and optimally meet the needs of the HX50 helicopter.

The Hill GT50 employs component and gas-path design delivering unmatched efficiencies for an entry-level turbine. The performance and operating range for the compressor and turbines is coupled with an efficient and robust three-can combustor system, offering a low-risk development route, flameout redundancy and fuel flexibility.

The historically expensive and heavy compressor turbine gearbox of current helicopter engines has been eliminated and replaced by a direct-drive starter-generator to reduce the cost and mechanical complexity of the engine. Extensive use of redundant electrical engine ancillaries further simplifies the engine package and a modular design makes for easy maintenance of the unit's core components. The engine is also fully electronically controlled and features the Hill FADEC system, providing rapid startup and shutdown, tight RPM management and optimal engine monitoring and control.

Additionally, the Hill team took advantage of today's economies of scale in manufacturing turbine components. On-demand advanced manufacturing processes and improved supply chains for the specialised materials used in turbine engines allowed for significant cost and time savings in developing, manufacturing and delivering an affordable new engine.

“The availability of reliable, powerful and affordable engines is what limits light helicopter design today,” Hill adds. “When considering the overall mix of requirements necessary to power a truly ground-breaking aircraft, we saw the opportunity to design a simple turbine engine with unmatched efficiency, power and cost. In simple terms, by developing the advanced GT50 engine, Hill has completely unlocked the potential of the helicopter in terms of both performance and cost, providing the enchanting opportunity to relaunch general aviation.”